1 /

1

Cleanroom

- Our price:USD$

- PriceUSD$

- Use bonus pointspt.

- High air flow to dilute the smoke

- Smoke will travel with air flow and not reach the ceiling

- Contamination is not acceptable in a clean room even for a small fire.

- The following are smoe extracts of standards from the international Fire Code and Taiwan Fire Code regarding the fire detection requirement in Cleanrooms.

NFPA 318 Standard for the Protection of Semiconductor Fabrication Facilities

11.1.3 Detection Systems.

11.1.3.1* Smoke Detection System. A listed or approved smoke detection system shall be provided in the cleanroom return airstream.

11.1.3.1.1 Detection shall be permitted to be accomplished using aspirating smoke detection (air sampling–type smoke detection) or spot-type detection systems.

11.1.3.2 Smoke detection within a cleanroom shall result in an alarm transmission to a supervising station as well as a local alarm signal within the cleanroom that is distinctive from both the facility audible alarm signal and any process equipment alarm signals in the cleanroom.

11.1.3.3 Smoke detection shall be listed to operate in the airflow velocities anticipated within the cleanroom.

11.1.3.4 The cleanroom smoke detection system shall be designated as either a property protection system or a life safety system based on a risk assessment.

11.1.3.4.1 Where a cleanroom smoke detection system is designated as a life safety system, a fire evacuation signal shall be issued when the detection system detects smoke at the levels specified in 11.1.3.5.2.

11.1.3.4.2 Where a cleanroom smoke detection system is designated as a property protection system, an investigation shall be carried out immediately by the site emergency response team on receipt of an alert signal being received at the supervising station.

11.1.3.4.3 Where a cleanroom smoke detection system is designated as a property protection system, a fire evacuation signal shall not be required to be issued automatically following an alert signal from the cleanroom smoke detection system.

11.1.3.5 Where smoke detection is installed below a waffle floor to detect smoke in the airstream passing from the clean‐ room to the sub-fab, area of coverage of spot-type detector or sampling port shall be limited to 18.6 m2 (200 ft2).

11.1.3.5.1 The minimum alert sensitivity for a single sampling port or spot-type detector shall be a maximum value of 0.65 percent/meter (0.2 percent/foot).

11.1.3.5.2 The minimum alarm sensitivity for a single sampling port or spot-type detector shall be a maximum value of 3.2 percent/meter (1.0 percent/foot).

11.1.3.6* In the absence of performance-based design criteria, where smoke detection is installed at the entry to the return air path, area coverage of spot-type detector or sampling port spacing shall be limited to 0.4 m2 (4.3 ft2).

11.1.3.6.1 The minimum alert sensitivity for a single sampling port or spot-type detector shall be a maximum value of 0.65 percent/meter (0.2 percent/foot).

11.1.3.6.2 The minimum alarm sensitivity for a single sampling port or spot-type detector shall be a maximum value of 3.2 percent/meter (1.0 percent/foot).

11.1.3.7 For an air sampling–type system, the maximum trans‐ port time from the most remote sampling port to the detection unit shall not exceed 60 seconds.

11.1.3.8 Smoke detection systems shall be maintained in accordance with NFPA 72.

11.2.6 Pyrophoric Liquids Cabinets.

11.2.6.1 Fire Detection System. Each cabinet shall be equipped with an automatic fire detection system that complies with the following conditions:

(1) Automatic detection system: A UV/IR, high-sensitivity smoke detection (HSSD) or other approved detection system shall be provided inside each cabinet.

(2) Automatic shutoff: Activation of the detection system shall automatically close the shutoff valve(s) on the liquid supply.

Taiwan Fire Protection Regulation in Cleanroom (effect starting from January 1, 2017)

Clean room area, Air Plenum, Return Air Plenum and Bridge shall be equipped with automatic fire detector or Aspirating Type Detector as according to the design principle circulating air flow and space. The signal from fire detector shall be reported and integrated into the fire alarm panel or other control equipment facilities. As for the return air shaft fire detection requirement, should be equipped with an aspirating smoke detection system

When configure or setting Aspirating Smoke Detector, it shall fulfill the below requirement:

Alarm Sensitivity is better than 0.6 Obscuration / meter.

Sampling pie network location, shall follow below requirement/regulation:

Within 30 centimeters below the upper return air ceiling

The distance between the clean room ceiling and the lower return air layer lattice floor slab is within 80 cm, and the sampling hole must not be below the lattice floor slab

In the return air shaft or at the cooling dry coil, clean the circulating airflow before the air is mixed with fresh air. However, the clean circulating airflow and the fresh air are not mixed in the return air shaft (as shown in Figure 3).• Sampling hole monitoring area, shall fulfill below requirement/regulation:

- When ASD and sampling hole is located at the upper return air layer, the effective detection range of each sampling hole is calculated by the effective detection range of the smoke detector.

- When ASD and sampling hole is installed in a clean room, the effective detection range of each sampling hole shall not exceed 36 (thirty six) square meters

- When ASD and sampling hole is installed in the lower return air layer, the effective detection range of each sampling hole shall not exceed 10 (ten) square meters

- When ASD and sampling hole is installed in the return air shaft or cooling the dry coil, the effective detection range of each sampling hole shall not exceed 1 (one) square meter

The protection area of each detector group shall comply with the Fire Safety and Protection Law of Article 120. However, when the ASD device is installed in the lower return air layer, return air shaft or cooling dry coil, the protection area of each detector group should meet the approval of the central fire control authority

When the detected particle concentration reaches to the threshold setting value, it should be able to issue a Warning signal; when the detected concentration reaches the Alarm Threshold setting value, it should be able to issue an Alarm Signal.

The air transport time from the last sampling hole from each branch should not exceed 120 seconds.

Each sampling pipe air flow condition shall be monitored for any abnormal situation.

The sampling tube network should be able Air Flow calculation and configuration which shall fulfill the principle of flow dynamic.

ASD detector should be installed in an easy-to-maintain position.

ASD Sampling tube network should be properly airtight and fixed

8. It shall have clear marking for ASD equipment installed for the clean room, the lower return air layer and the pipe bridge area. The requirement of the equipment marking shall according to the special requirements of color temperature and light of the production process. If the automatic fire alarm system or aspirating smoke detector is to be connected notification light, it is allow that the notification light to be dimmed or light off.

9. Clean room area shall review the installation of smoke extraction equipment in accordance with the of Fire Safety and Protection Law Article 28. Exception of installation of smoke extraction equipment are as according to below guideline.

(1) Fire Resistant materials are used for the building.

(2) The escape route or walking distance complies with Article 93 of the Building Design and Construction Code.

(3) The building employs Aspirating Smoke Detection system.

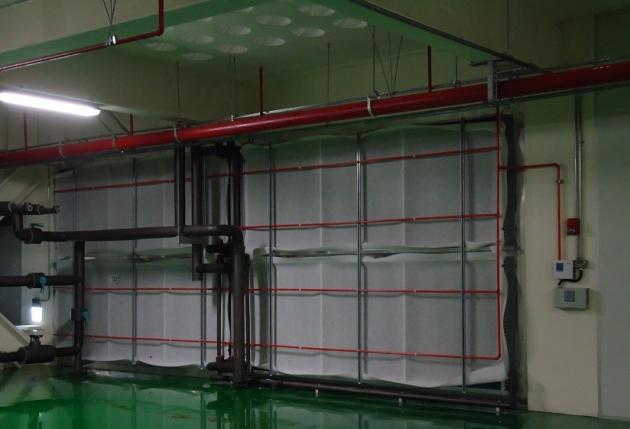

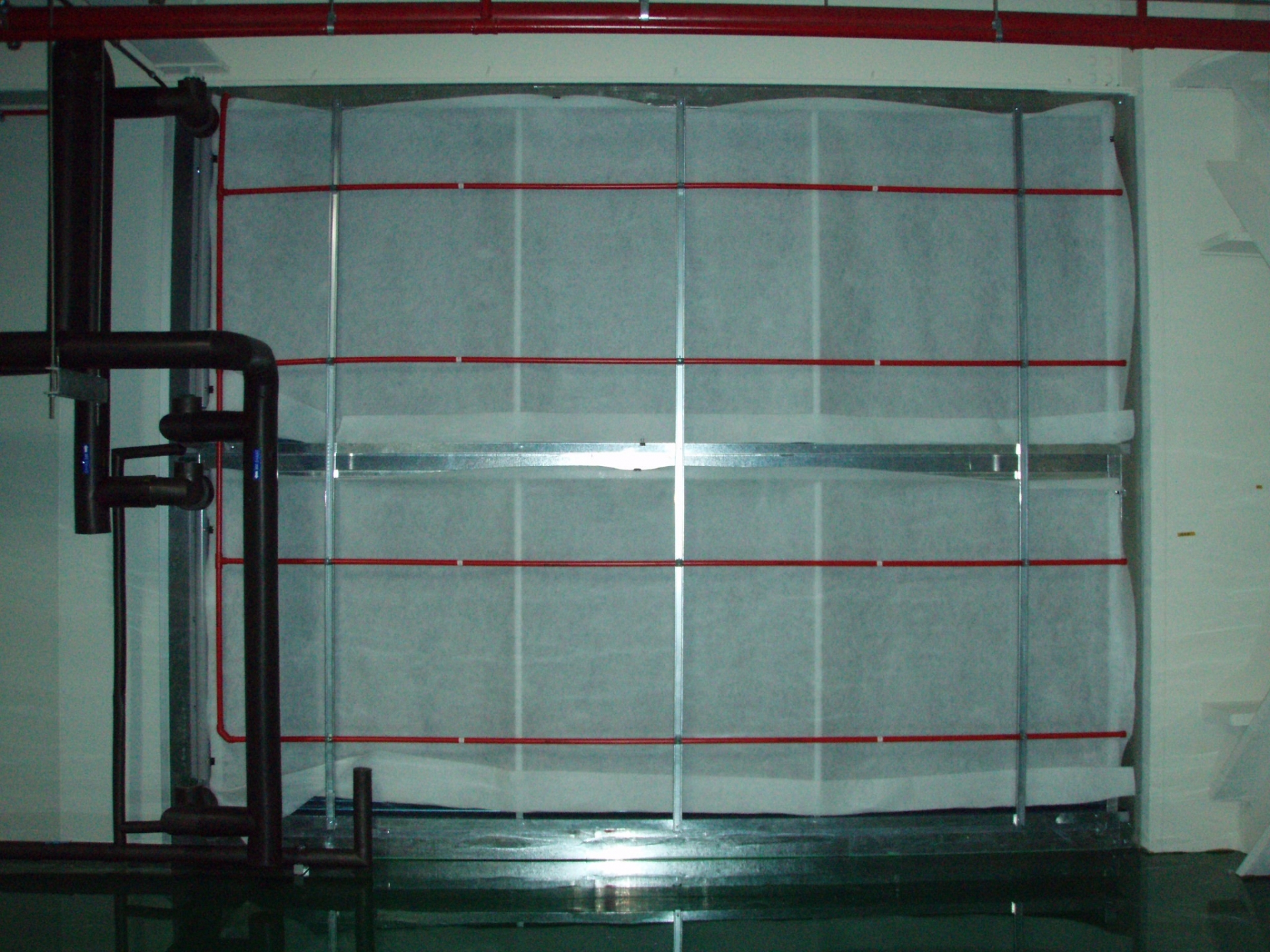

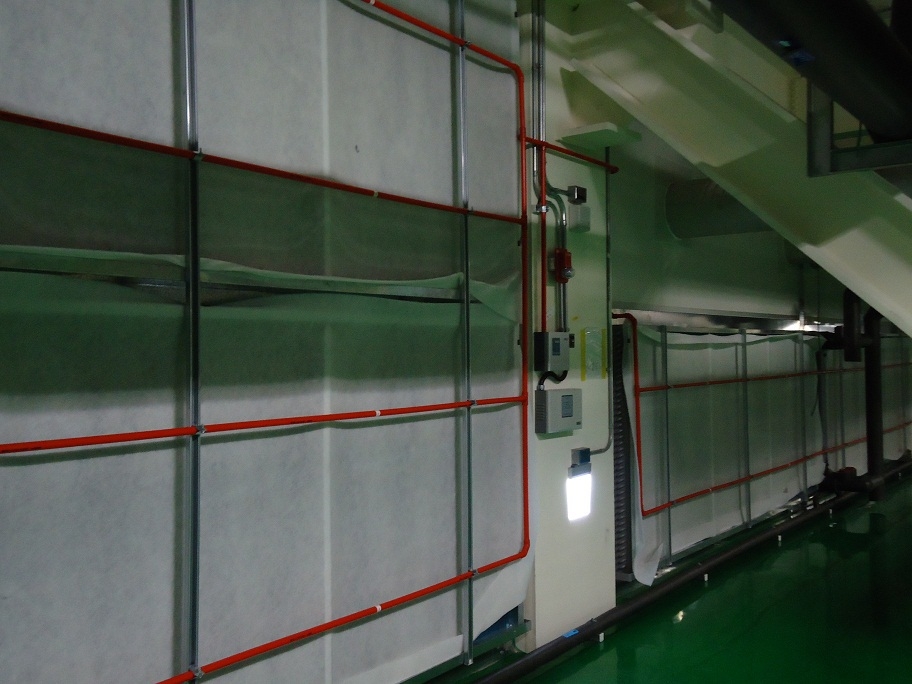

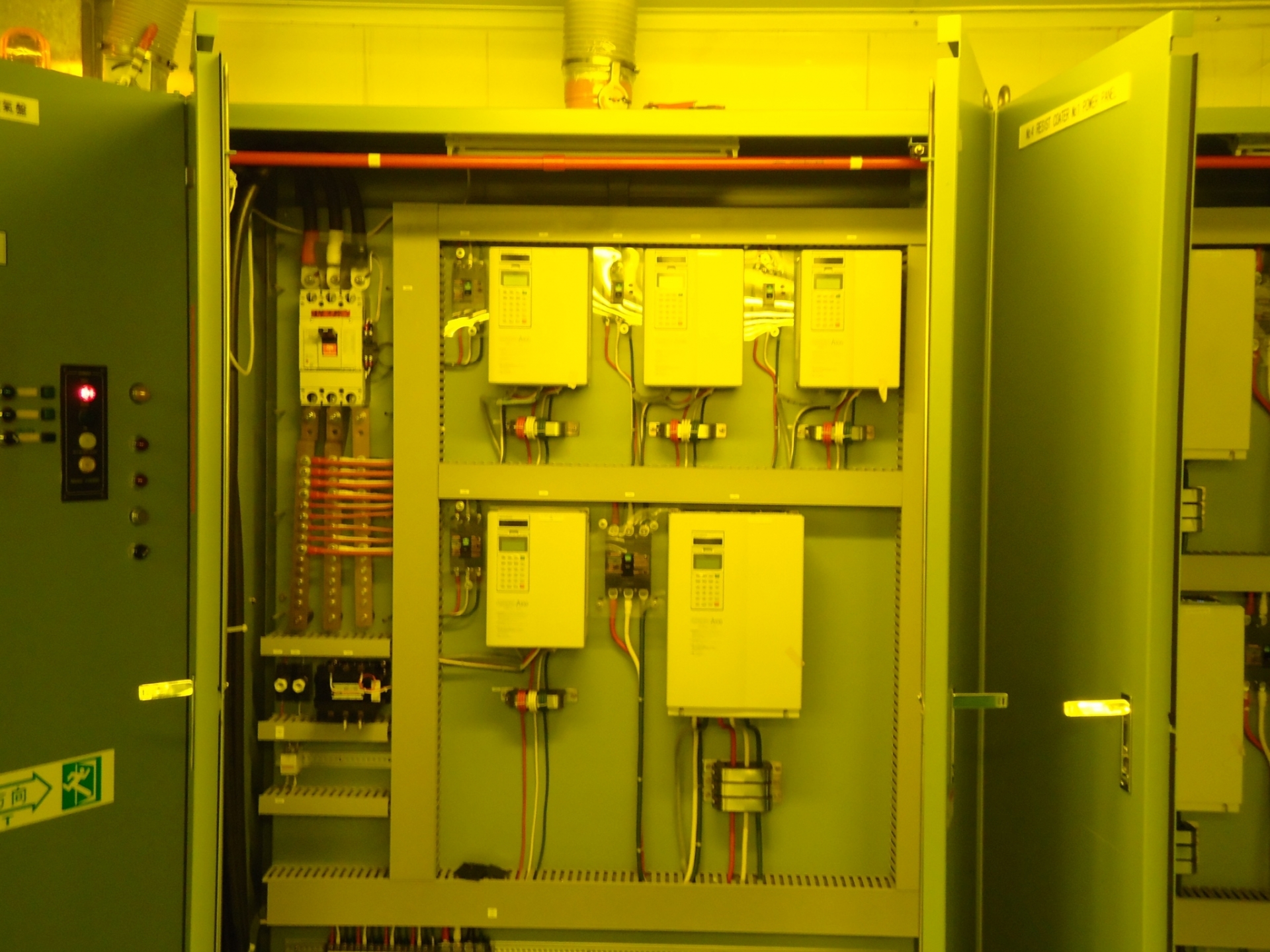

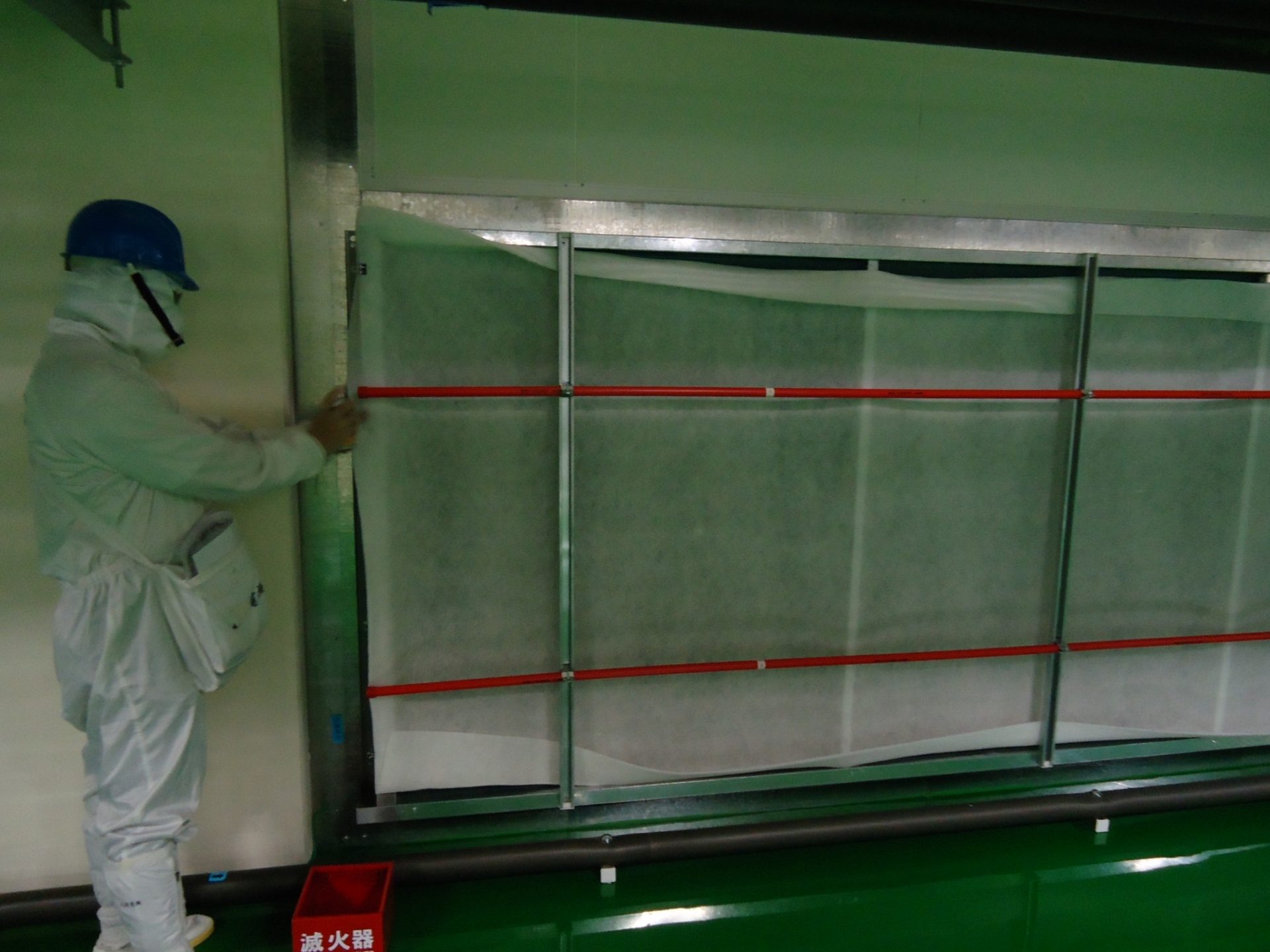

Cleanroom Project Photos

- Our price:USD$

- PriceUSD$