- Discounted price:USD$

- Our price:USD$

- PriceUSD$

- Use bonus pointspt.

Ensure the normal operation of power system is very important in modern society. Whether it is the production of factories, communication and network services, transportation, hospitals and medical tasks, when the power supply is interrupted by problems with electricity and related facilities, all work will come to a halt. The time required to return to normal from a fire can range from tens of minutes to days or even up to several months, and the damage can be incalculable.

Short circuit, insulation deterioration, poor contact, high temperature, and overload of current are the main causes of fires in electrical rooms or switchboards. It is very important to detect any equipment anomalies as early as possible to avoid fires or minimize the loss and impact of fires.

Electrical room / Electrical cabinet fire detection difficulties

|

Point type smoke detector is the most common type of detector in the electrical room, they are usually installed under the ceiling. There are three factors that will affect the effectiveness of smoke detection.

We should understand the main factors influencing the prolonged detection and increased losses due to the installation of detectors in the electrical equipment environment. |

Equipment Enclosure

Due to the hazards associated with the high voltage of power facilities and distribution systems, these devices are often confined in enclosures. The enclosures may be equipped with internal cooling fans or air conditioning systems to keep equipment temperatures within safe limits. These enclosures have two negative effects on the travel time of the smoke detectors at the site:

-

The cabinet enclosure will restrict the flow of smoke, prolonging the time it takes for the smoke to leave the fire source and reach the ceiling-mounted detector.

-

The internal fan and air conditioning system will dilute and cool the smoke so that it does not have sufficient thermal buoyancy to rise to the ceiling, prolonging the response time of the detectors on the ceiling.

The sensitivity of traditional smoke detectors is low.

When there is smoke inside the cabinet, most of it will be contained by the cabinet, and even if some of the smoke leaks into the room, it will spread out and dilute, and it cannot reach the smoke concentration required for the smoke detector at the ceiling to generate alarms.

Typical application of aspirating smoke detection system for electrical room / cabinets fire protection

To solve the above-mentioned problems faced by the traditional smoke detector in the electrical room / panels application, the typical approach is to use aspirating (or air sampling) smoke detection system as a fire detection solution for electrical rooms / panels, in order to effectively and early detection of internal fire in the electrical room and panels.

The operation of the aspirating smoke detection system is to use the aspirator inside the detector to connect the air sampling pipes and capillary tubes extending to the cabinets to extract the air samples inside the cabinets and send them back to the detector unit for air sample measurement, and to give a fire alarm when the detector unit senses an abnormal increase in smoke concentration.

Typical installation of an air sampling smoke detection system where all air samples from the cabinet are sent back to the detection unit through capillary tubes into the sampling pipes for smoke detection.

The detection system was unable to identify the location of the cabinet where the fire occurred

Since the air samples from the cabinets are eventually merged into the detector, when the detector detects an abnormal increase in smoke, there is no way to know which cabinet is causing the problem, so all cabinets must be opened one by one to find the source of the fire. This is a very high stress for personnel on site and time consuming. The advantage of very early warning can be compensated by the time it takes to locate the source of the fire.

In addition, the function and fire risk of each cabinet may be different, so if the air sampling piping network is incorporated only because of its location, it is impossible to link the corresponding contingency measures according to the function or importance of different cabinets, which also diminishes the advantage of the very early warning system.

The influence of the number of cabinets on fire sensitivity

|

When an aspirating smoke detector protects more cabinets, due to the effect of smoke dilution, the fire inside the cabinet need a higher concentration of smoke to make the detection system to give an alarm.

For example, a detection system to protect 20 electrical panels, the smoke dilution ratio of 1/20, when the detector fire sensitivity threshold value of 0.2 %/m, then smoke from the fire source electrical panels must reach 0.2 %/m × 20 = 4 %/m in order to make the detector to trigger the alarm.

If this system protects 50 electrical panels, the smoke dilution ratio is 1/50, then the smoke concentration of the fire source must reach 0.2%/m×50=10% before the fire alarm can be released.

That is to say, the more electrical panels are protected, the lower the system sensitivity of the aspirating detection system, then the meaning of very early warning is lost.

|

The CSD is designed in such a way that each detector protects only one cabinet, so that in case of abnormal smoke generation in any one cabinet, there is no need to search all cabinets one by one and locate the fire location directly when the alarm is generated. In addition to locating the cabinet where the fire occurred, the CSD protects only one cabinet, which means that the smoke dilution is minimized, so that the system will have a very high sensitivity and can provide very early fire warning signals when the fire is still in incipient stage and the amount of smoke generated is still small.

CSD is the perfect solution for electrical room / panel fire detection, as it can provide extremely early warning and locating the cabinet where the fire occurred.

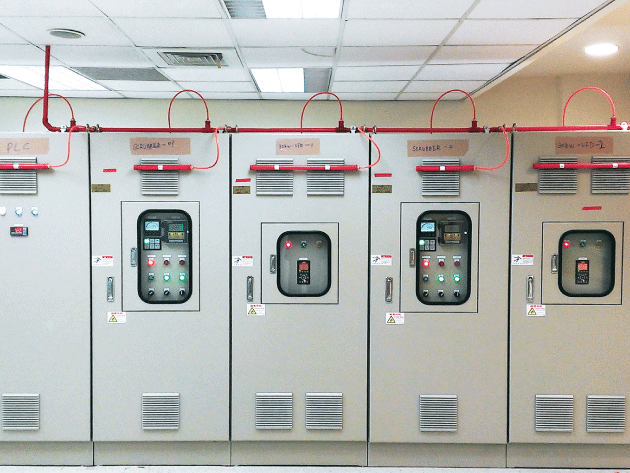

Electrical Room / Cabinet Application Photos

CSD-100 Electrical Cabinet In-Cabinet Sampling

CSD-100 Electrical Cabinet In-Cabinet Sampling

CSD-100 Electrical Cabinet In-Cabinet and Exhaust Grille Sampling

FANFARE-4000 Electrical Cabinet In-Cabinet and Exhaust Grille Sampling

FANFARE-4000 Electrical Cabinet In-Cabinet and Exhuast Grille Sampling

FANFARE-4000 Electrical Cabinet In-Cabinet and Exhaust Grille Sampling

QUARTAS-500 Electrical Cabinet In-Cabinet and Exhaust Grille Sampling

QUARTAS-2000 Electrical Cabinet In-Cabinet Sampling

QUARTAS-2000 Aboe Cabinet Sampling

QUARTAS-2000 Electrical Room AHU Return Air Sampling

CSD-100 345KV Line Protection Cabinet Smoke Detetion

CSD-100 345KV Line Protection Cabinet Smoke Detection

PARTIAL CUSTOMER LIST

Taiwan Power Company

- TPC

Ban-Qiao Jing-Xing Substation: SSTR Panel

Hsin-Chu1st Substation: SSTR Panel

Zhu-Wei 161KV EHV Substation: Electric Room

Miao-Li Tong-Luo: Substation - Shanghai Municipal Electric Power

High Tech Factory

- Cxmt Hefei (12-inch fab)

- Kunshan CHIMEI Materials Technology Corporation

- Mantix Display Technology

- HKC Display Technology Chongqing Jinyu Optoelectronics

- Sdi Corporation Rainbow Photovoltaic Power Plant 3.5 Generation Factory

- KFES Lighting (Xiamen)

- UMC 8S Plant: Electric Room

- Unimicron Xing-Ban 2nd Plant: Electric Room

- Ablytek Solar Energy Pingtung Plant: Electric Room

- WIN Semiconductor Corp

1st Plant: Cleanroom

Guishan Plant: Cleanroom - HannsTouch Solution Incorporated Tainan Fab: Cleanroom

- Realtek Semiconductor Corp: Electric Room

- CHI MEI Corporation ABS Plant: Substation

- Crystalwise Technology Inc. Chunan Plant: Electric Room & IT Room

- PAN JIT INTERNATIONAL INC.: Electric Room and Cleanroom

- BASF MEP Taichung: Electric Room

- Hermes Microvision Inc. Tainan Plant:Cleanroom/Electric Room/IT Room

- Epistar Actualize LED

N3 Plant

N8 Plant

S1 Plant

S3 Plant

Taichung H Plant - TAIWAN Huga Optotech Inc

- Tanida Clean Room

- Unitech printed circuit board corp

- HSMC Wuhan Hongxin Semiconductor Manufacturing

Telecom/IDC

- Taiwan Stock Exchange Yang De Building

- Chunghwa Post: Electric Room/Server Room/Office/UPS

Taipei Control Center

Taichung Backup Center - Chief Telecom: UPS Room/Batteries

- Chunghwa Telecom Mobile

Communication Branch Nangang site: Mobile Telecommunication Room

Chunghwa Telecom Renai Building 1, 2, 3, 7 Floor (Taiwan Stock Exchange): Data Center

Chunghwa Telecom Banqiao Data Center (18K)

Chunghwa Telecom Banqiao, Hualian, Hsinchu, Miaoli, Xinzhuang: Data Center

Chunghwa Telecom Mobile Communication Branch Kaohsiung Shiquan/Juemin/ ErlingTa, Tainan Yongkang, Taichung Changer:Mobile Telecommunication Room

Hydropower Fire

Very early equipment for new construction (18K) - Taiwan Mobile

Taichung 14 Plant

Neihu IDC computer room - Far EasTone Telecommunications:UPS Room/Battery Room/Electric Room

PC326

NH468

Taichung(1F&4F)

Petroleum

- Nan Ya Plastics

Shu-Lin No.3 Plant: Electric Room

Mai-Liao 2EH Plant: Electric Room

Mai-Liao EG1 Plant: Electric Room

Mai-Liao EG2 Plant: Electric Room

Miao-Liao INA Plant: Electric Room

Xin-Gang Glass Fabrics No.1 Plant: Electric Room

Xin-Gang Glass Fabrics No.4 Plant: Electric Room - Formosa Plastics Mai-Liao

MMA Plant & SAR II Plant

AE Plant

AN Plant

C4 Plant

EVA Plant

ECH Plant

HDPE Plant

LLPE Plant

SAP Plant

VCM Plant

PE Technical Office

PVC Plant

Soda plant

Carbon Fiber Factory

Inspection Center

Xu Elastic Fiber Factory

Storage Area of Chemical Department - Formosa Plastic Ren

Wu Alkaline Plant

Wu Plant Plastic 2nd Section: UPS Room - Eternal Materials Da-Fa Factory

Switchgear, Production Line

Cleanroom - CPC Da-in Factory, KAOHSIUNG

Project 1: All Electric Rooms, Refinery 3

Project 2: Substation #3

Project 3: All Electric Rooms, Refinery 1

Project 4: 161KV, R-CHAW & KAOSUNG TANK FARM

Project 5: RFCC Load Center #10

Project 6: Substations, Sulfur Recovery Unit #4 & gas hydrogen desulfurization #2

Project 7: MCC Panel Room, Alkylation Unit

CPC

- Chien-Cheng Petrochemical Storage Center: All MCC Panels

- Lin-Yuan Factory: Substation

- Tao-Yuan Factory: Wu-Gu & Sha - Lun Petrochemical Storage Center

- Yao-Yuan Factory: Substation #9 and Substation #1

- LNG Yong-An Factory: Substation #2 and Substation #7

Steel Plant

- China Steel Corp

Electric Rooms, W5/Power 2nd Plant

W5/Power 1st Plant & Turbine House - TS Steel CO., LTD.: Electric Room

- Dragon Steel

Airport

- International Airport

Taoyuan

Kaohsiung

Songshan - Pingtung Air Station

Laboratory

- National Nano Device Laboratories: Cleanroom

- Hua-chuang Automobile Information Technical Center: Battery Laboratory

Others

- Taichin Global: Boiler/Electric Room

- Formosa TV Linkou Headquarter

- Banqiao Affordable Housing: Electric Room

- Discounted price:USD$

- Our price:USD$

- PriceUSD$