High Power Blue LED Detection Light Source

Exploring the development of detection light sources

It has been 40 years since Dr. Martin Cole of IEI Australia successfully commercialized the expensive and complex laboratory grade nephelometers and created the unique category of air sampling smoke detection in fire alarm systems under the brand name VESDA (Very Early Smoke Detection Apparatus) in the 1980's. This type of product has also progressed with the development of modern technology, and the most obvious development is probably the evolution of the detection light source.

In the 1980s, the first generation of VESDA air sampling smoke detectors used a Xenon Lamp as the detection source. Xenon lamps are very bright and are full-spectrum, with wavelengths ranging from short to long wavelengths in the spectrum, making them sensitive to all sizes of airborne particulates and excellent for smoke detection performance. However, the cost of a xenon lamp is high, and its brightness decreases over time. As a result, the detectors need to be calibrated every 2 years and future operation and maintenance costs are high.

After IEI’s merger with Vision Systems Ltd in 1995, this new aspirator was incorporated into the next model detector known as VESDA LaserPlus. The full-spectrum Xenon lamp design of previous VESDA models was replaced with a solid-state, infra-red laser light source, which offered improved maintenance at the expense of reduced sensitivity to small particles.

As a matter of fact, with the development and popularization of semiconductor laser technology in the 1990s, it is natural that different manufacturers and their products developed in the 1990s (including Kidde Hart Laser, AirSense Stratos-HSSD and VESDA LaserPLUS) have used infrared lasers as detection light sources. The advantages of infrared lasers are long lifetime and very high light intensity at the focal point of the beam, which can produce very strong scattered light from airborne particles passing through the focal point of the laser beam. However, since infrared lasers are monotonic, with a wavelength of 940nm, they are less sensitive to small particles because of their longer wavelength. The second-generation infrared laser light source solved the cost and lifespan problems, but it also sacrificed sensitivity to small particles in a fire.

In the 21st century, with the rapid development of LED technology, LEDs not only become brighter, but also have a longer lifespan. The invention of high-brightness blue LEDs has led to the creation of energy-efficient and bright white light sources. Therefore, the use of LEDs is no longer limited to indicators, but has begun to be used in a variety of applications. Therefore, it seems only natural that most of the air sampling smoke detectors introduced in the 21st century use high-brightness LEDs as the detection light source, including Monitair which launched in 2005 by the founder of VESDA, Dr. Martin Cole and called it the 3rd generation of air sampling smoke detectors (now acquired by Siemens).

After comparing various technologies in the research and development stage, AVA's products adopt high power blue LED as the detection light source. Compared to other light sources with longer wavelengths, blue light's short wavelength of 470nm is more sensitive to small particles, and can effectively detect smoke of all sizes. The blue light source has the advantages of both the 1st generation xenon light source and the 2nd generation infrared laser light source, but without the disadvantages of both, making it an ideal light source for high sensitivity smoke detection.

Light Scattering Principle

Airborne particulates have a size distribution ranging from about 0.01 to 100 µm. Smoke particles are generally smaller, ranging from 0.01 to several µm; and dust particles are generally larger, ranging from a few µm to tens of µm. According to light scattering theory, the intensity of scattered light depends on the size of the particle and the wavelength of the incident light. When the size of the particle and the wavelength of the incident light are equivalent, light scattering is considered Mie Scattering, and when the size of the particle is much smaller than the wavelength of the incident light, light scattering is considered Rayleigh Scattering.

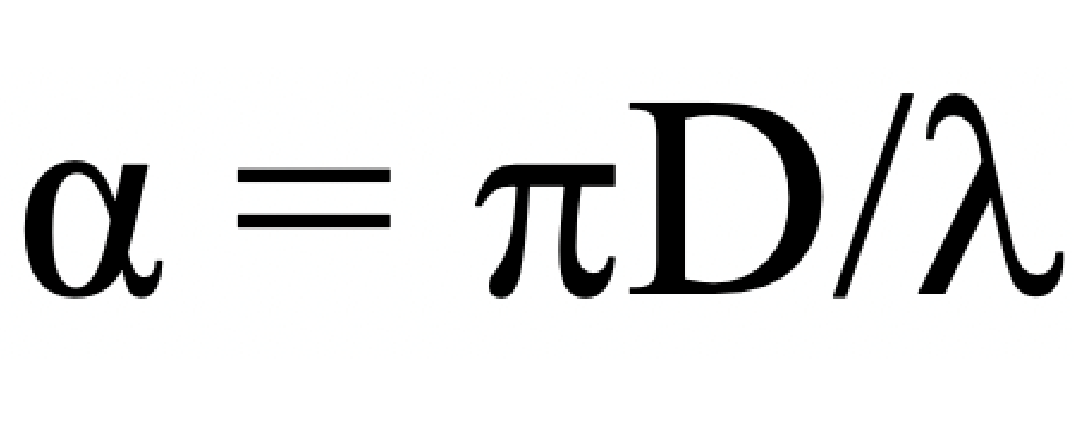

The particle size can be represented by the parameter α:

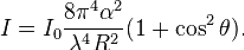

where D is the particle size and λ is the wavelength of the incident light. When α is less than 0.1, Rayleigh scattering is applicable. When λ is between 0.1 and 50, Mie scattering is applicable. The equations for Mie scattering and Rayleigh scattering are as follows

Rayleigh scattering:

Mie scattering:

When comparing the wavelengths of infrared and blue light sources, the wavelengths of infrared light (laser or LED) is 760nm (0.76µm) and the wavelength of blue light (laser or LED) is 470nm (0.47µm). The smaller the particle size (e.g., 0.01 to 0.1µm), the smaller the scattering is (e.g., less than 0.015µm). The Rayleigh scattering is inversely proportional to the fourth power of the wavelength. Therefore, theoretically, for very small particles of smoke in the air, the scattered light intensity produced by the short-wavelength blue light and the long-wavelength infrared light will be 6.8:1, which means that the scattered light intensity of the blue light will be 6.8 times that of the infrared light. For large smog particles in the air, the scattered light intensity will be 2.6:1, which is 2.6 times that of infrared light, when Mie scattering is used to calculate the scattered light, and the scattered light intensity will be 2.6 times that of infrared light.

As a result, compared to products that use an infrared laser as a detection light source, AVA blue light sources are more sensitive to smoke particles, especially small smoke particles. This is important for fire detection because smoke particles from incipient or smoldering fires are smaller than those from later combustion stages, making blue light sources an advantage for detecting fires in the very early stages.

Large Volume Detection

Another feature of the AVA blue LED light source is that it detects smoke samples in "three dimensions" instead of "points".

The laser beam is strongest only at the focal point of the beam, so its smoke detection method is in fact equivalent to a Particle Counter, which converts the number of scattered light pulses generated in a unit time by smoke particles passing through the focal point of the beam into a smoke concentration, detecting a single particle at a time.

Although the brightness of the LED is not as high as that of the laser beam and the scattered light produced by a single particle is not as good as that of the laser beam, the total scattered light signal is very large due to the large number of particles, and the scattered light intensity is proportional to the total mass of all the suspended particles.

Detector Calibration

In summary, due to the fact that high power blue LED light sources are more sensitive to smoke particles than infrared laser light sources, and the scattered light intensity varies depending on the particle size, smaller size smoke particles can produce greater scattered light intensity. Therefore, the smoke detector of AVA products is calibrated based on the larger particle size so that the sensitivity output of AVA products is comparable to that of infrared laser products when smoke with larger particle size is generated by fire combustion. In this way, when a fire generates small particle size smoke (or during the incipient stage of a fire), the sensitivity output is much higher than that of an infrared laser type product.

Figure: Smoke density at different particle sizes of the calibrated AVA product and the infrared laser light source product.

Comparison of Experimental Data

The following figure shows the ratio of the concentration of smoke produced by the combustion of various substances between AVA products and the products using infrared laser as the light source. As it can be seen from the figure, the AVA using blue LEDs is more sensitive than the product using infrared laser for all material combustion smoke tests.